C1207 Left Rear Wheel Speed Excessive Variation

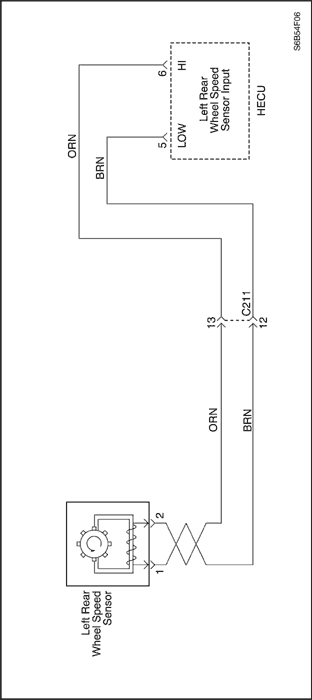

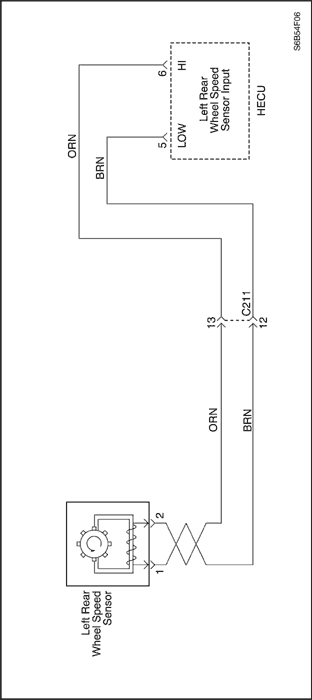

Circuit Description

As the wheel is rotated, the speed sensor produces an AC voltage that increases with wheel speed. The HECU uses the frequency of the AC signal to calculate wheel speed. The speed sensor is connected to the HECU by a "twisted pair" of wires. Twisting reduces noise susceptibility that may cause a DTC to set.

Conditions for Setting the DTC

All of the following must be true for C1207 to set.

- C1200 or C1203 or C1206 or C1209 not current.

- Brake switch off.

- The left rear wheel speed is accelerating or decelerating beyond reasonable limits.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power from the pump motor and solenoids.

- DTC C1207 is stored.

- ABS disabled, ABS Warning Lamp turns on.

Conditions for Clearing the DTC

- If the conditions that set DTC C1207 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

Thoroughly inspect the wiring and connectors when diagnosing intermittent DTC(s). This will include the following.

- Removal of the protective conduit and inspection for wiring for damage, shorts and contamination.

- Inspection for improperly formed and/or damaged terminals.

- Checking terminal contact (retention force) by using a spare male/female terminal.

- Removal of the terminals from the connectors to check for proper terminal to wire crimp.

If the drivers comments reflect that the ABS Warning Lamp is on only during moist environmental changes (rain, snow, vehicle wash), all wheel speed sensor circuitry should be thoroughly inspected for signs of water intrusion. If the DTC is not current, simulate the effects of water intrusion. Use the following procedure. Spray the suspected area with a 5 percent salt-water solution. Then test-drive the vehicle over various road surfaces such as (bumps, turns, etc) above 24 kph (15 mph). If the DTC sets then replace the suspected harness and/or sensor.

A careful visual inspection of the toothed ring for damaged such as cracks and tooth damage should be performed. If the DTC sets at the same speed every drive cycle, the toothed ring is most likely damaged.

Failure to perform the previous steps carefully and fully can result in misdiagnosis, unnecessary component replacement and reoccurrence of DTC C1207.

C1207 Left Rear Wheel Speed Excessive Variation

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check prior to performing DTC C1207 trouble chart. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | Was C1206 set as a current or history DTC? | - | Go to Step 4 | Go to Step 5 |

| 4 | Perform C1206 diagnostic chart prior to performing DTC C1207 trouble chart. | - | System OK | - |

| 5 | - Ignition switch "OFF".

- Inspect the left rear wheel speed sensor and the jumper harness for damage.

- Perform a complete and thorough inspection of the left rear toothed ring for damage. (cracks, missing teeth, looseness)

Is any physical damage noted? | - | Go to Step 6 | Go to Step 7 |

| 6 | Repair the damage to the left rear wheel speed sensor, jumper harness and/or the toothed ring. | - | System OK | - |

| 7 | - Vehicle in park.

- Connect a Scan Tool and select data list.

- Monitor the wheel speed sensors.

- Start the vehicle, and monitor wheel speed sensors with engine running but vehicle not moving.

- Lightly depress the accelerator pedal to increase engine idle speed.

Did C1207 reset or did the left rear wheel speed read above 0 mph when the vehicle was in park with the engine running. | - | Go to Step 8 | Go to Step 9 |

| 8 | The cause of C1207 is ignition noise coupled onto the Left Rear Speed Sensor circuits. Inspect the routing of the left rear ABS body harness and/or jumper harness for potential ignition noise sources such as spark plug wires. Reroute wiring as needed.. | - | System OK | - |

| 9 | - Scan tool still connected.

- Monitor the wheel speed sensors.

- Test-drives the vehicle up to the maximum-posted speed limit, and slowly decelerates to zero. Do this several times.

Did C1207 reset or did the left rear wheel speed vary more than 5 kph (3 mph) when compared to any one of the other wheels during the drive? | - | Go to Step 11 | Go to Step 10 |

| 10 | DTC C1207 is intermittent, refer to Diagnostic Aids. | - | System OK | - |

| 11 | - Vehicle in park, Ignition switch "OFF".

- Raise and suitably support the vehicle.

- Disconnect the left rear jumper harness from the Left Rear Wheel Speed sensor.

- Connect an ohmmeter to terminals 1 and 2 of the Left Rear Wheel Speed sensor.

Is the resistance within the specified range? | 800-1600 Ohms (Resistance will vary with temperature) | Go to Step 13 | Go to Step 12 |

| 12 | Replace the left rear wheel speed sensor. | - | System OK | - |

| 13 | - Speed sensor still disconnected from the jumper harness.

- Connect a voltmeter to terminals 1 and 2 of the left rear speed sensor.

- Select the AC milli-volt scale.

- Spin the left rear wheel while observing the voltage on the meter.

Is the AC voltage within the specified range? | At least 100mV | Go to Step 14 | Go to Step 12 |

| 14 | - Disconnect the HECU harness from the HECU.

- Disconnect the left rear jumper harness from the ABS body harness

- Connect an ohmmeter to HECU harness terminal 5 and then to ABS body harness terminal 1.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 16 | Go to Step 15 |

| 15 | Repair the source open or high resistance between terminals 5 and 1. | - | System OK | - |

| 16 | - HECU harness still disconnected from the HECU.

- Jumper harness still disconnected from the body harness.

- Connect an ohmmeter to HECU harness terminal 6 and then to ABS body harness terminal 2.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 18 | Go to Step 17 |

| 17 | Repair the open or high resistance between terminals 6 and 2. | - | System OK | - |

| 18 | - HECU harness still disconnected from the HECU.

- Jumper harness still disconnected from the body harness.

- Connect an ohmmeter between HECU harness terminals 5 and 6.

Is the resistance within the specified range? | OL(open circuit) | Go to Step 20 | Go to Step 19 |

| 19 | Repair the short between the 2 wires. | - | System OK | - |

| 20 | - Replace the left rear jumper harness.

- Test-drive the vehicle at various speeds and road surfaces.

Did C1207 reset? | - | Go to Step 21 | System OK |

| 21 | Replace the HECU. | - | System OK | - |

C1208 Left Rear Wheel Speed Sensor No Signal

Circuit Description

As the wheel is rotated, the speed sensor produces an AC voltage that increases with wheel speed. The HECU uses the frequency of the AC signal to calculate wheel speed. The speed sensor is connected to the HECU by a "twisted pair" of wires. Twisting reduces noise susceptibility that may cause a DTC to set.

Conditions for Setting the DTC

All of the following must be true for C1208 to set.

- C1200 or C1203 or C1206 or C1209 not current.

- ABS not active.

- Brake switch off.

- The left rear wheel speed equals 0, and all of the remaining Wheel Speed Sensors are greater than 8 km/hr (5 mph) for at least 2.5 seconds.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power from the pump motor and solenoids.

- DTC C1208 is stored.

- ABS disabled, ABS Warning Lamp turns on.

Conditions for Clearing the DTC

- If the conditions that set DTC C1208 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

Thoroughly inspect the wiring and connectors when diagnosing intermittent DTC(s). This will include the following.

- Removal of the protective conduit and inspection of wiring for damage, shorts and contamination.

- Inspection for improperly formed and/or damaged terminals.

- Checking terminal contact (retention force) by using a spare male/female terminal.

- Removal of the terminals from the connectors to check for proper terminal to wire crimp.

If the drivers comments reflect that the ABS Warning Lamp is on only during moist environmental changes (rain, snow, vehicle wash), all wheel speed sensor circuitry should be thoroughly inspected for signs of water intrusion. If the DTC is not current, simulate the effects of water intrusion. Use the following procedure. Spray the suspected area with a 5 percent salt-water solution. Then test-drive the vehicle over various road surfaces such as (bumps, turns, etc) above 24 kph (15 mph). If the DTC sets then replace the suspected harness and/or sensor.

When measuring wheel speed sensor resistance insures the vehicle is at room temperature, since resistance will increase with temperature.

Failure to perform the previous steps carefully and fully can result in misdiagnosis, unnecessary component replacement and reoccurrence of DTC C1208.

C1208 Left Rear Wheel Speed Sensor No Signal

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check prior to performing this trouble tree. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | - Ignition switch "OFF".

- Inspect the left front wheel speed sensor, jumper harness and toothed ring for physical damage.

Is any physical damage noted? | - | Go to Step 4 | Go to Step 5 |

| 4 | Repair the damage to the left rear wheel speed sensor, jumper harness and/or toothed ring. Check the airgap. | 0.2~0.8mm | System OK | - |

| 5 | Was DTC C1206 set as a current or history code? | - | Go to Step 6 | Go to Step 7 |

| 6 | Perform diagnostics for DTC C1206 prior to performing this table. | - | System OK | - |

| 7 | - Connect a Scan Tool and select data list.

- Monitor the wheel speed sensors.

- Test-drives vehicle above 24 kph (15 mph) and slowly decelerates to zero, do this several times.

Did C1208 reset or did the left rear wheel speed suddenly drop to zero prior to the vehicle coming to a complete stop? | - | Go to Step 9 | Go to Step 8 |

| 8 | DTC C1208 is intermittent. Refer to diagnostic aids. | - | System OK | - |

| 9 | - Ignition switch "OFF".

- Raise and suitably support the vehicle.

- Disconnect the HECU harness from the HECU.

- Connect a voltmeter to HECU harness terminals 6 and 5.

- Select the AC mill volt scale.

- Spin the left front wheel while observing the voltmeter. (voltage should increase as wheel speed increases)

Is the AC voltage within the specified range? | At least 100mV | Go to Step 10 | Go to Step 11 |

| 10 | Replace the HECU. | - | System OK | - |

| 11 | - Disconnect the left rear jumper harness from the Left Rear Wheel Speed Sensor.

- Connect an ohmmeter to terminals 1 and 2 of the Left Rear Wheel Speed Sensor.

Is the resistance within the specified range? | 800-1600 Ohms (Resistance will vary with temperature) | Go to Step 13 | Go to Step 12 |

| 12 | Replace the left rear wheel speed sensor. | - | System OK | - |

| 13 | - Left Rear jumper harness still disconnected from the left rear speed sensor.

- Connect a voltmeter to terminals 1 and 2 of the left rear wheel speed sensor.

- Select the AC mill volt scale.

- Spin the left rear wheel while observing the voltmeter. (voltage should increase as wheel speed increases)

Is the AC voltage within the specified range? | At least 100mV | Go to Step 14 | Go to Step 12 |

| 14 | - Disconnect the left rear jumper harness from the ABS body harness.

- HECU harness still disconnected from the HECU.

- Connect an ohmmeter to HECU harness terminals 5 and 6.

Is the Resistance within the specified range? | OL(open circuit) | Go to Step 16 | Go to Step 15 |

| 15 | Find and repair the short between the 2 circuits. | - | System OK | - |

| 16 | - HECU harness still disconnected from the HECU.

- Left rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 5 and then to ABS body harness terminal 1.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 18 | Go to Step 17 |

| 17 | Repair the open or high resistance between terminals 5 and 1. | - | System OK | - |

| 18 | - HECU harness still disconnected from the HECU.

- Left rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 6 and then to ABS body harness termi 2.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 20 | Go to Step 19 |

| 19 | Repair the open or high resistance between terminal 6 and 2. | - | System OK | - |

| 20 | - Replace the left rear wheel speed jumper harness.

- Test-drive the vehicle at various speeds and road surfaces.

Did C1208 reset? | - | Go to Step 10 | System OK |

C1209 Right Rear Wheel Speed Sensor Circuit Open or Shorted

Circuit Description

As the wheel is rotated, the speed sensor produces an AC voltage that increases with wheel speed. The HECU uses the frequency of the AC signal to calculate wheel speed. The speed sensor is connected to the HECU by a "twisted pair" of wires. Twisting reduces noise susceptibility that may cause a DTC to set.

Conditions for Setting the DTC

DTC C1209 can be set anytime the key is on and the HECU has detected an open, short to ground or a short to battery on the right rear wheel speed circuit.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power to the pump motor and solenoids.

- DTC C1209 is stored.

- ABS disabled, ABS Warning Lamp turns on.

Conditions for Clearing the DTC

- If the conditions that set DTC C1209 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

Thoroughly inspect the wiring and connectors when diagnosing intermittent DTC(s). This will include the following.

- Removal of the protective conduit and inspection to wiring for damage, shorts and contamination.

- Inspection for improperly formed and/or damaged terminals.

- Checking terminal contact (retention force) by using a spare male/female terminal.

- Removal of the terminals from the connectors to check for proper terminal to wire crimp.

If the drivers comments reflect that the ABS Warning Lamp is on only during moist environmental changes (rain, snow, vehicle wash), all wheel speed sensor circuitry should be thoroughly inspected for signs of water intrusion. If the DTC is not current, simulate the effects of water intrusion. Use the following procedure. Spray the suspected area with a 5 percent salt-water solution. Then test-drive the vehicle over various road surfaces such as (bumps, turns, etc) above 24 kph (15 mph). If the DTC sets then replace the suspected harness and or sensor.

When measuring wheel speed sensor resistance insure the vehicle is at room temperature, since resistance will increase with temperature.

Failure to perform the previous steps carefully and fully can result in misdiagnosis, unnecessary component replacement and reoccurrence of DTC C1209.

C1209 Right Rear Wheel Speed Sensor Circuit Open or Shorted

| Step | Action | Value(s) | Yes | No |

| 1 | Was the diagnostic circuit check performed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | - Ignition switch "OFF".

- Inspect the right rear wheel speed sensor, jumper harness and the toothed ring for physical damage.

Is any physical damage noted? | - | Go to Step 4 | Go to Step 5 |

| 4 | Repair the damage to the right rear wheel speed sensor, jumper harness and/or toothed ring. | - | System OK | - |

| 5 | Test-drive vehicle at various speeds and over various road surfaces. Did C1209 reset? | - | Go to Step 7 | Go to Step 6 |

| 6 | DTC C1209 is intermittent. Refer to Diagnostic Aids. | - | System OK | - |

| 7 | - Ignition switch "OFF", vehicle in park.

- Raise and suitably support the vehicle.

- Disconnect the right rear jumper harness from the Right Rear Wheel Speed Sensor.

- Connect an ohmmeter to terminals 2 and 1 of the Right Rear Wheel Speed Sensor.

Is the resistance with in specified range?. | 800-1600 Ohms (Resistance will vary with temperature) | Go to Step 9 | Go to Step 8 |

| 8 | Replace the right rear wheel speed sensor. | - | System OK | - |

| 9 | - Right Rear jumper harness still disconnected from the speed sensor.

- Connect an ohmmeter to terminal 2 of the right rear wheel speed sensor and then to body ground.

Is the resistance within the specified range? | OL(open circuit) | Go to Step 10 | Go to Step 8 |

| 10 | - Disconnect the HECU harness from the HECU.

- Disconnect the right rear jumper harness from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 23 and then the ABS body harness terminal 1.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 12 | Go to Step 11 |

| 11 | Repair the open or high resistance between terminals 23 and 1. | - | System OK | - |

| 12 | - HECU harness still disconnected from the HECU.

- Right Rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 22 and then to ABS body harness terminal 2.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 4 | Go to Step 13 |

| 13 | Repair the open or high resistance between terminals 22 and 2. | - | System OK | - |

| 14 | - HECU harness still disconnected from the HECU.

- Right Rear jumper harness still disconnected from the ABS body harness.

- Connect a voltmeter to HECU harness terminal 23 and then to body ground.

Is the voltage within the specified range? | Less than 1volt | Go to Step 16 | Go to Step 15 |

| 15 | Repair the short to voltage between terminals 23 and 1. | - | System OK | - |

| 16 | - HECU harness still disconnected from the HECU.

- Right Rear jumper harness still disconnected from the ABS body harness.

- Connect a voltmeter to HECU harness terminal 22 and then to body ground.

Is the voltage within the specified range? | Less than 1volt | Go to Step 18 | Go to Step 17 |

| 17 | Repair the short to voltage between terminals 22 and 2. | - | System OK | - |

| 18 | - HECU harness still disconnected from the HECU.

- Right Rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 23 and then to body ground.

Is the resistance within the specified range? | OL(open circuit) | Go to Step 20 | Go to Step 19 |

| 19 | Repair the short to ground between terminals 23 and 1. | - | System OK | - |

| 20 | - HECU harness still disconnected from the HECU.

- Right Rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 22 and then to body ground.

- Connect an ohmmeter to HECU harness terminal 23 and then to body ground. Is the resistance within the specified range?

Is the resistance within the specified range? | OL(open circuit) | Go to Step 22 | Go to Step 21 |

| 21 | Repair the short to ground between terminals 22 and 2. | - | System OK | - |

| 22 | - HECU harness still disconnected from the HECU.

- Right Rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 23 and 22.

Is the resistance within the specified range? | OL(open circuit) | Go to Step 24 | Go to Step 23 |

| 23 | Repair the short between the 2 circuits. | - | System OK | - |

| 24 | - Replace the Right Rear Wheel Speed Sensor Jumper Harness.

- Test-drive the vehicle at various speeds and various road surfaces.

Did C1209 reset? | - | Go to Step 25 | System OK |

| 25 | Replace the HECU. | - | System OK | - |

C1210 Right Rear Wheel Speed Excessive Variation

Circuit Description

As the wheel is rotated, the speed sensor produces an AC voltage that increases with wheel speed. The HECU uses the frequency of the AC signal to calculate wheel speed. The speed sensor is connected to the HECU by a "twisted pair" of wires. Twisting reduces noise susceptibility that may cause a DTC to set.

Conditions for Setting the DTC

All of the following must be true for C1210 to set.

- C1200 or C1203 or C1206 or C1209 not current.

- Brake switch off.

- The right rear wheel speed is accelerating or decelerating beyond reasonable limits.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power from the pump motor and solenoids.

- DTC C1210 is stored.

- ABS disabled, ABS Warning Lamp turns on.

Conditions for Clearing the DTC

- If the conditions that set DTC C1210 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

Thoroughly inspect the wiring and connectors when diagnosing intermittent DTC(s). This will include the following.

- Removal of the protective conduit and inspection for wiring for damage, shorts and contamination.

- Inspection for improperly formed and/or damaged terminals.

- Checking terminal contact (retention force) by using a spare male/female terminal.

- Removal of the terminals from the connectors to check for proper terminal to wire crimp.

If the drivers comments reflect that the ABS Warning Lamp is on only during moist environmental changes (rain, snow, vehicle wash), all wheel speed sensor circuitry should be thoroughly inspected for signs of water intrusion. If the DTC is not current, simulate the effects of water intrusion. Use the following procedure. Spray the suspected area with a 5 percent salt-water solution. Then test-drive the vehicle over various road surfaces such as (bumps, turns, etc) above 24 kph (15 mph). If the DTC sets then replace the suspected harness and/or sensor.

A careful visual inspection of the toothed ring for damaged such as cracks and tooth damage should be performed. If the DTC sets at the same speed every drive cycle, the toothed ring is most likely damaged.

Failure to perform the previous steps carefully and fully can result in misdiagnosis, unnecessary component replacement and reoccurrence of DTC C1210.

C1210 Right Rear Wheel Speed Excessive Variation

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check prior to performing DTC C1210 trouble chart. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | Was C1210 set as a current or history DTC? | - | Go to Step 4 | Go to Step 5 |

| 4 | Perform C1209 diagnostic chart prior to performing DTC C1210 trouble chart. | - | System OK | - |

| 5 | - Ignition switch "OFF".

- Inspect the right rear wheel speed sensor and the jumper harness for damage.

- Perform a complete and thorough inspection of the right rear toothed ring for damage. (cracks, missing teeth, looseness)

Is any physical damage noted? | - | Go to Step 6 | Go to Step 7 |

| 6 | Repair the damage to the right rear wheel speed sensor, jumper harness and/or the toothed ring. | - | System OK | - |

| 7 | - Vehicle in park.

- Connect a Scan Tool and select data list.

- Monitor the wheel speed sensors.

- Start the vehicle, and monitor wheel speed sensors with engine running but vehicle not moving.

- Lightly depress the accelerator pedal to increase engine idle speed.

Was C1210 reset or the right rear wheel speed read above 0 mph when the vehicle was in park with the engine running. | - | Go to Step 8 | Go to Step 9 |

| 8 | The cause of C1210 is ignition noise coupled onto the Right Rear Speed Sensor circuits. nspect the routing of the right rear ABS body harness and/or jumper harness for potential ignition noise sources such as spark plug wires. Reroute wiring as needed. | - | System OK | - |

| 9 | - Scan tool still connected.

- Monitor the wheel speed sensors.

- Test-drives the vehicle up to the maximum-posted speed limit, and slowly decelerates to zero. Do this several times.

Was C1210 reset or the right rear wheel speed vary more than 5 kph (3 mph) when compared to any one of the other wheels during the drive? | - | Go to Step 11 | Go to Step 10 |

| 10 | DTC C1210 is intermittent, refer to Diagnostic Aids. | - | System OK | - |

| 11 | - Vehicle in park, Ignition switch "OFF".

- Raise and suitably support the vehicle.

- Disconnect the right rear jumper harness from the Right Rear Wheel Speed sensor.

- Connect an ohmmeter to terminals 2 and 1 of the Right Rear Wheel Speed sensor.

Is the resistance within the specified range? | 800-1600 Ohms (Resistance will vary with temperature) | Go to Step 13 | Go to Step 12 |

| 12 | Replace the right rear wheel speed sensor. | - | System OK | - |

| 13 | - Speed sensor still disconnected from the jumper harness.

- Connect a voltmeter to terminals 2 and 1 of the right rear speed sensor.

- Select the AC milli-volt scale.

- Spin the right rear wheel while observing the voltage on the meter.

Is the AC voltage within the specified range? | At least 100mV | Go to Step 14 | Go to Step 12 |

| 14 | - Disconnect the HECU harness from the HECU.

- Disconnect the left rear jumper harness from the ABS body harness

- Connect an ohmmeter to HECU harness terminal 23 and then to ABS body harness terminal 1.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 16 | Go to Step 15 |

| 15 | Repair the source open or high resistance between terminals 23 and 1. | - | System OK | - |

| 16 | - HECU harness still disconnected from the HECU.

- Jumper harness still disconnected from the body harness.

- Connect an ohmmeter to HECU harness terminal 22 and then to ABS body harness terminal 2.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 18 | Go to Step 17 |

| 17 | Repair the open or high resistance between terminals 22 and 2. | - | System OK | - |

| 18 | - HECU harness still disconnected from the HECU.

- Jumper harness still disconnected from the body harness.

- Connect an ohmmeter between HECU harness terminals 23 and 22.

Is the resistance within the specified range? | OL(open circuit) | Go to Step 20 | Go to Step 19 |

| 19 | Repair the short between the 2 wires. | - | System OK | - |

| 20 | - Replace the right rear jumper harness.

- Test-drive the vehicle at various speeds and road surfaces.

Did C1210 reset? | - | Go to Step 21 | System OK |

| 21 | Replace the HECU. | - | System OK | - |

C1211 Right Rear Wheel Speed Sensor No Signal

Circuit Description

As the wheel is rotated, the speed sensor produces an AC voltage that increases with wheel speed. The HECU uses the frequency of the AC signal to calculate wheel speed. The speed sensor is connected to the HECU by a "twisted pair" of wires. Twisting reduces noise susceptibility that may cause a DTC to set.

Conditions for Setting the DTC

All of the following must be true for C1211 to set.

- C1200 or C1203 or C1206 or C1209 not current.

- ABS not active.

- Brake switch off.

- The right rear wheel speed equals 0, and all of the remaining Wheel Speed Sensors are greater than 8 km/hr (5 mph) for at least 2.5 seconds.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power from the pump motor and solenoids.

- DTC C1211 is stored.

- ABS disabled, ABS Warning Lamp turns on.

Conditions for Clearing the DTC

- If the conditions that set DTC C1211 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

- Thoroughly inspect the wiring and connectors when diagnosing intermittent DTC(s). This will include the following.

- Removal of the protective conduit and inspection of wiring for damage, shorts and contamination.

- Inspection for improperly formed and/or damaged terminals.

- Checking terminal contact (retention force) by using a spare male/female terminal.

- Removal of the terminals from the connectors to check for proper terminal to wire crimp.

If the drivers comments reflect that the ABS Warning Lamp is on only during moist environmental changes (rain, snow, vehicle wash), all wheel speed sensor circuitry should be thoroughly inspected for signs of water intrusion. If the DTC is not current, simulate the effects of water intrusion. Use the following procedure. Spray the suspected area with a 5 percent salt-water solution. Then test-drive the vehicle over various road surfaces such as (bumps, turns, etc) above 24 kph (15 mph). If the DTC sets then replace the suspected harness and/or sensor.

When measuring wheel speed sensor resistance insures the vehicle is at room temperature, since resistance will increase with temperature.

Failure to perform the previous steps carefully and fully can result in misdiagnosis, unnecessary component replacement and reoccurrence of DTC C1211.

C1211 Right Rear Wheel Speed Sensor No Signal

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check prior to performing this trouble tree. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | - Ignition switch "OFF".

- Inspect the right rear wheel speed sensor, jumper harness and toothed ring for physical damage.

Is any physical damage noted? | - | Go to Step 4 | Go to Step 5 |

| 4 | Repair the damage to the right rear wheel speed sensor, jumper harness and/or toothed ring. Check the airgap. | 0.2~0.8mm | System OK | - |

| 5 | Was DTC C1209 set as a current or history code? | - | Go to Step 6 | Go to Step 7 |

| 6 | Perform diagnostics for DTC C1209 prior to performing this table. | - | System OK | - |

| 7 | - Connect a Scan Tool and select data list.

- Monitor the wheel speed sensors.

- Test-drives vehicle above 24 kph (15 mph) and slowly decelerates to zero, do this several times.

Did C1211 reset or did the left rear wheel speed suddenly drop to zero prior to the vehicle coming to a complete stop? | - | Go to Step 9 | Go to Step 8 |

| 8 | DTC C1211 is intermittent. Refer to diagnostic aids. | - | System OK | - |

| 9 | - Ignition switch "OFF".

- Raise and suitably support the vehicle.

- Disconnect the HECU harness from the HECU.

- Connect a voltmeter to HECU harness terminals 23 and 22.

- Select the AC mill volt scale.

- Spin the right rear wheel while observing the voltmeter. (voltage should increase as wheel speed increases)

Is the AC voltage within the specified range? | At least 100mV | Go to Step 10 | Go to Step 11 |

| 10 | Replace the HECU. | - | System OK | - |

| 11 | - Disconnect the right rear jumper harness from the Right Rear Wheel Speed Sensor.

- Connect an ohmmeter to terminals 2 and 1 of the Right Rear Wheel Speed Sensor.

Is the resistance within the specified range? | 800-1600 Ohms (Resistance will vary with temperature) | Go to Step 13 | Go to Step 12 |

| 12 | Replace the right rear wheel speed sensor. | - | System OK | - |

| 13 | - Right Rear jumper harness still disconnected from the left rear speed sensor.

- Connect a voltmeter to terminals 2 and 1 of the right rear wheel speed sensor.

- Select the AC mill volt scale.

- Spin the right rear wheel while observing the voltmeter. (voltage should increase as wheel speed increases)

Is the AC voltage within the specified range? | At least 100mV | Go to Step 14 | Go to Step 12 |

| 14 | - Disconnect the right rear jumper harness from the ABS body harness.

- HECU harness still disconnected from the HECU.

- Connect an ohmmeter to HECU harness terminals 23 and 22.

Is the Resistance within the specified range? | OL(open circuit) | Go to Step 16 | Go to Step 15 |

| 15 | Find and repair the short between the 2 circuits. | - | System OK | - |

| 16 | - HECU harness still disconnected from the HECU.

- Right rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 23 and then to ABS body harness terminal 1.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 18 | Go to Step 17 |

| 17 | Repair the open or high resistance between terminals 23 and 1. | - | System OK | - |

| 18 | - HECU harness still disconnected from the HECU.

- Right rear jumper harness still disconnected from the ABS body harness.

- Connect an ohmmeter to HECU harness terminal 22 and then to ABS body harness terminal 2.

Is the resistance within the specified range? | Less than2 ohms | Go to Step 20 | Go to Step 19 |

| 19 | Repair the open or high resistance between terminal 22 and 2. | - | System OK | - |

| 20 | - Replace the right rear wheel speed jumper harness.

- Test-drive the vehicle at various speeds and road surfaces.

Did C1211 reset? | - | Go to Step 10 | System OK |

C1604 HECU Internal Fault

Circuit Description

This DTC identifies a possible malfunction within the HECU.

Conditions for Setting the DTC

- DTC C1604 will set when a possible internal component/microprocessor problem may exist.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power from the pump motor and the solenoids.

The ABS and DDRP are disabled

- DTC C1604 is stored.

- ABS Warning Lamp and Brake Warning Lamp are turned on.

Conditions for Clearing the DTC

- If the conditions that set DTC C1604 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

- When C1604 is displayed on the scan tool, it should be followed by two additional numbers (xx) which should be documented along with any other DTC(s) that may be displayed.

- Repair low voltage, driveability, or other electrical complaints first, prior to performing C1604 trouble tree.

- Make sure the integrity of the connection between the HECU and the BPMV is secure, tight and free of corrosion, leaks and/or damage.

C1604 HECU Internal Fault

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | - Install scan tool.

- Turn ignition ON, with engine OFF.

- Using scan tool, observe DTC information.

Dose any DTC(s) set in Current or History Data other than C1604? | Battery must hold above 9.6 volts for 10 secondsNo greater than 30 mA of draw | Go to Step 4 | Go to Step 5 |

| 4 | Perform the applicable DTC diagnostic for the other DTC(s). | - | System OK | - |

| 5 | - Ignition switch "OFF".

- Disconnect the harness from the HECU.

- Check the connectors for damage, corrosion, and terminal contact.

Were any problems found? | - | Go to Step 6 | Go to Step 7 |

| 6 | Repair as needed. | - | System OK | - |

| 7 | Replace the HECU. | - | System OK | - |

C2112 Valve Relay or Fuse Failure

Circuit Description

This DTC identifies a possible malfunction within the HECU. When the HECU relay is activated (turned on), voltages is supplied to the valve solenoids and pump motor.

Conditions for Setting the DTC

- DTC C2112 will set when possible internal malfunctions exist.

Action Taken When the DTC Sets

- ABS Warning Lamp is not turned on.

- DTC C2112 is stored.

- ABS remains functional.

Conditions for Clearing the DTC

- If the conditions that set DTC C2112 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

- Repair low voltage, driveability, or other electrical complaints first, prior to performing C2112 trouble tree.

- Make sure the integrity of the connection between the HECU and the BPMV is secure, tight and free of corrosion, leaks and/or damage.

- Possible cause for DTC C2112 to set is an internal relay problem within HECU.

C2112 Valve Relay or Fuse Failure

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | - Install scan tool.

- Turn ignition ON, with engine OFF.

- Using scan tool, observe DTC information.

Does scan tool display any DTC(s) set in Current or History Data other than C2112? | Battery must hold above 9.6 volts for 10 secondsNo greater than 30 mA of draw | Go to Step 4 | Go to Step 5 |

| 4 | Perform the applicable DTC diagnostic for the other DTC(s). | - | System OK | - |

| 5 | - Ignition switch "OFF".

- Disconnect the harness from the HECU.

- Check the resistance between the terminal 25 of the wiring harness connector and ground.

Was the resistance within the specified range? | ≈ 0 Ω | Go to Step 7 | Go to Step 6 |

| 6 | - Check the fuse Ef5 from the engine room fuse block. And check the connectors for damage, corrosion and terminal contact including the terminal 25.

- Repair as needed.

- Go to Step 3.

| - | - | - |

| 7 | Replace the HECU. | - | System OK | - |

C2402 Pump Motor Failure

Circuit Description

The pump motor is contained within the Brake Pressure Modulator Valve (BPMV). The pump motor ground is supplied though terminal 24 of the HECU.

Conditions for Setting the DTC

C2402 can only be set with the key in the ON position, pump motor is commanded off just after a run command, and the HECU detected a seized or slowly moving pump motor.

Action Taken When the DTC Sets

- The solenoid relay opens, removing power from the pump motor and solenoids.

- The DTC C2402 is stored.

- ABS disabled and the ABS Warning Lamp illuminates.

Conditions for Clearing the DTC

- If the conditions that set DTC C2402 are no longer present, the DTC may be cleared by using the proper scan tool.

- The DTC that has not occurred in 100 drive cycles will be cleared from history data.

Diagnostic Aids

Typical causes of DTC C2402.

- Poor terminal contact at terminal 24.

- Terminal 24 ground circuit high resistance.

- Terminal 24 ground circuit open.

- BPVM pump motor malfunction.

- HECU malfunction.

C2402 Pump Motor Failure

| Step | Action | Value(s) | Yes | No |

| 1 | Was the Diagnostic Circuit Check Completed? | - | Go to Step 3 | Go to Step 2 |

| 2 | Perform the Diagnostic Circuit Check. Did you find problem? | - | Go to Step 3 | System OK |

| 3 | - Ignition switch "OFF".

- Disconnect the negative battery cable.

- Disconnect HECU harness from the HECU.

- Connect an ohmmeter to the negative battery cable and terminal 24 of the HECU harness.

Was the resistance reading within the specified range? | Less than2 ohms | Go to Step 5 | Go to Step 4 |

| 4 | Find and repair the source of high resistance between the HECU ground circuit and chassis ground. | - | System OK | - |

| 5 | - Follow the negative battery cable to the engine block and/or chassis ground connection and inspect for a good clean and tight connection.

- From terminal 24 of the HECU harness follow the wire and find the location where the circuit grounds to the chassis. Inspect for a good clean and tight connection.

Were both connections clean and tight | - | Go to Step 7 | Go to Step 6 |

| 6 | Repair the poor ground connection. | - | System OK | - |

| 7 | - HECU harness still disconnected.

- Remove the HECU from the BPMV.

- Inspect the HECU to BPMV connector for conditions such as damage, corrosion, poor terminal contact, or the presence of brake fluid.

Were the terminals and connector OK, and the cavity free of brake fluid, damage and corrosion? | - | Go to Step 9 | Go to Step 8 |

| 8 | - If damage and/or corrosion are present, replace the HECU and/or the BPMV as necessary.

- If the brake fluid is present, replace both the HECU and the BPMV.

| - | System OK | - |

| 9 | Connect an ohmmeter to terminal 1 and terminal 2 of the BPMV. Was the pump motor resistance reading within the specified range? | Less than2 ohms | Go to Step 11 | Go to Step 10 |

| 10 | Replace the Brake Pressure Modulator Valve. | - | System OK | - |

| 11 | Replace the HECU. | - | System OK | - |

| |  | |

| © Copyright Chevrolet Europe. All rights reserved |